Rigging and Lifting Handbook PDFs⁚ A Comprehensive Guide

Numerous online resources offer rigging and lifting handbooks in PDF format. These range from comprehensive guides covering fundamental principles to specialized manuals focusing on specific equipment or industries. Many emphasize safety practices and legal compliance, providing crucial information for safe operations.

Available Resources and Formats

Rigging and lifting handbooks are widely available in various formats, primarily as downloadable PDF files. Many sources offer these handbooks for free, while others may require a purchase or subscription. The formats can vary; some are concise guides focusing on specific aspects of rigging, while others are extensive manuals covering a broader range of topics and equipment. You can often find these resources on industry websites, professional organizations’ sites, and online marketplaces specializing in technical documentation. The quality and comprehensiveness of the handbooks can differ significantly, so careful selection is crucial. Look for reputable sources and check reviews before downloading. Some handbooks may be tailored to specific industries or types of lifting equipment, ensuring relevance to your particular needs. Remember to verify the currency and accuracy of the information provided, as safety regulations and best practices can evolve over time.

Key Safety Considerations Emphasized in Handbooks

Safety is paramount in rigging and lifting operations, and reputable handbooks heavily emphasize crucial safety protocols. These often include detailed explanations of weight limits, load capacity calculations, and proper sling selection and attachment techniques. Handbooks stress the importance of regular equipment inspections to identify and address wear, damage, or potential defects. Safe working practices, such as using appropriate personal protective equipment (PPE) and adhering to established procedures, are consistently highlighted. Furthermore, emergency response protocols and procedures for dealing with accidents or equipment malfunctions are typically included. The handbooks frequently underscore the need for adequate training and certification for personnel involved in rigging and lifting activities. Understanding and applying these safety considerations is crucial for minimizing the risk of accidents and ensuring a safe working environment.

Types of Lifting Equipment Covered

Rigging and lifting handbooks typically cover a wide array of equipment used in various lifting applications. Commonly included are descriptions and safe operating procedures for cranes (including tower, mobile, and overhead cranes), hoists (electric, manual, and pneumatic), and winches. The handbooks often detail the specifications and safe usage of various types of slings, including wire rope slings, synthetic web slings, and chain slings. Information on shackles, hooks, and other rigging hardware is also usually provided, along with guidance on their proper selection and inspection. Furthermore, specialized lifting equipment such as vacuum lifters, air bags, and specialized lifting beams may be addressed, depending on the handbook’s scope and intended audience. Understanding the capabilities and limitations of each equipment type is crucial for safe and efficient lifting operations.

Specific Applications and Industries

Rigging and lifting handbooks often cater to specific industries and applications, offering tailored guidance. Construction is a major focus, with detailed explanations of lifting practices for building materials, prefabricated components, and heavy machinery. The manufacturing sector is another key area, covering the safe handling of large equipment, raw materials, and finished products within factories and plants. Oil and gas operations frequently utilize specialized lifting procedures for pipelines, drilling equipment, and offshore platforms, which are often addressed in dedicated sections. Similarly, the maritime industry requires specific guidelines for cargo handling and ship maintenance, often included in specialized handbooks. Other industries, such as power generation and transportation, may also have sections devoted to their unique lifting challenges and safety considerations. The level of detail and specific examples will vary depending on the handbook’s intended audience and area of specialization.

Understanding the Content of Rigging Handbooks

Rigging handbooks provide essential information on safe lifting practices, covering fundamental principles, advanced techniques, and hazard identification. They are crucial for ensuring workplace safety and regulatory compliance.

Fundamental Principles and Advanced Techniques

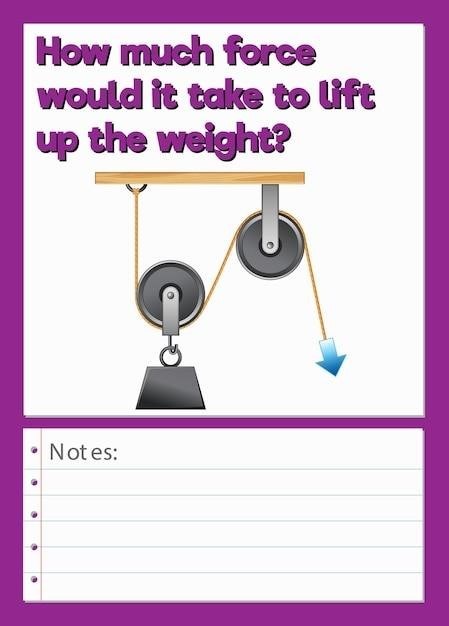

Rigging and lifting handbooks delve into the core principles of load bearing, weight distribution, and center of gravity calculations. They explain the physics behind safe lifting operations, emphasizing the importance of understanding load limits and stress factors. These handbooks move beyond the basics, exploring advanced techniques such as complex rigging configurations for unusual loads or challenging environments. Detailed illustrations and diagrams accompany explanations of knot tying, sling selection, and the proper use of various lifting devices. Furthermore, advanced sections might cover specialized lifting techniques, such as those used in construction, industrial settings, or marine operations. They often include detailed instructions on the use of specific equipment, like cranes, hoists, and winches, along with troubleshooting guides for common problems. The aim is to equip users with the knowledge to safely handle a wide range of lifting challenges, from simple to extremely complex tasks, minimizing the risk of accidents.

Safe Practices for Rigging, Lifting, and Landing Loads

Comprehensive rigging handbooks place significant emphasis on safe practices throughout the entire lifting process. Detailed procedures are provided for inspecting equipment before each lift, ensuring all components are in good working order and within their rated capacities. The handbooks stress the importance of proper communication and teamwork among all personnel involved in the lifting operation. Clear guidelines are outlined for selecting appropriate slings and rigging hardware based on load characteristics and environmental conditions. Safe lifting techniques are demonstrated, focusing on minimizing strain on equipment and personnel. Emphasis is placed on controlled lifting and lowering procedures, along with the importance of securing loads to prevent movement or accidental drops. The safe landing and placement of loads are also addressed, including techniques for minimizing impact and potential damage. These handbooks frequently include checklists and flowcharts to aid in maintaining safe practices and ensuring compliance with relevant regulations.

Hazard Identification and Safeguards

Rigging and lifting handbooks dedicate significant sections to identifying potential hazards and implementing effective safeguards. These manuals detail common hazards such as equipment failure, improper rigging techniques, and environmental factors like weather conditions. Specific procedures for conducting thorough pre-lift inspections are provided, highlighting potential weaknesses or damage in slings, ropes, hooks, and other components. The handbooks also emphasize the importance of load capacity calculations and the selection of appropriate equipment to match the weight and characteristics of the load. Safe working distances and exclusion zones are defined to protect personnel from falling objects or equipment malfunctions. Personal protective equipment (PPE) requirements, including hard hats, safety glasses, and gloves, are clearly outlined. Emergency procedures for handling equipment malfunctions or accidents are included, providing step-by-step guidance for safe response and mitigation. Detailed information on relevant safety regulations and standards is often integrated to ensure compliance and minimize liability.

Accessing and Utilizing Rigging and Lifting Handbooks

Reliable online resources, industry associations, and specialized publishers offer access to rigging and lifting handbooks. Careful selection of a handbook appropriate for your specific needs and regulatory compliance is crucial for safe and effective operations.

Finding Reliable Online Resources

Locating trustworthy rigging and lifting handbooks online requires careful consideration. Reputable sources include professional organizations like the Association of Crane and Rigging Professionals (ACRP) or the Crane Industry Service Bureau (CISB). These organizations often offer publications or links to reliable resources, ensuring the information is accurate and up-to-date with industry best practices and safety standards. Searching directly through established industry websites can also yield valuable results, providing access to both free and paid materials. Be wary of information found on less reputable sites, as the accuracy and safety standards might not be adequately vetted. Always check the author’s credentials and publication date to verify the information’s reliability and relevance. Cross-referencing information from multiple reliable sources is recommended to ensure complete understanding and adherence to best practices. Prioritize resources from government or industry-recognized bodies to avoid potentially misleading information that could compromise safety during lifting operations; Remember, using outdated or inaccurate information can lead to serious accidents.

Choosing the Right Handbook for Your Needs

Selecting the appropriate rigging and lifting handbook depends heavily on your specific requirements. Consider the types of lifting equipment you regularly use, the complexity of your operations, and your industry’s specific regulations. A general handbook might suffice for basic lifting tasks, while specialized guides are necessary for complex projects or specialized equipment like cranes or heavy machinery. Check the handbook’s scope to ensure it covers the necessary lifting techniques, safety procedures, and equipment types relevant to your work. Consider the handbook’s format and accessibility; a well-organized PDF with clear diagrams and illustrations is crucial for easy understanding and reference. The handbook’s language and level of detail should match your skill and experience level; beginners might need a more introductory handbook, while experienced professionals might require advanced techniques and detailed specifications. Finally, verify the handbook’s compliance with current safety regulations and industry standards; outdated information can lead to unsafe practices. The right handbook is an investment in safety and operational efficiency.

Legal and Regulatory Compliance

Rigging and lifting operations are subject to stringent legal and regulatory requirements designed to ensure workplace safety. Before using any rigging and lifting handbook, verify its compliance with all applicable local, national, and international standards. These regulations often dictate specific procedures, safety measures, and equipment requirements. Handbooks should clearly outline these requirements, providing guidance on how to meet legal obligations. Failure to comply with these regulations can result in significant penalties, including fines and legal action. The handbook should clearly identify the relevant standards and regulations it adheres to, allowing users to confirm its suitability for their specific location and operational context. Furthermore, the handbook should emphasize the importance of ongoing training and competency assessments for personnel involved in rigging and lifting activities to maintain compliance. Regular updates to the handbook are vital to reflect changes in legislation and best practices. Always prioritize safety and ensure all operations adhere to the current legal framework.